MAINPRESS

- Pressing System

MAINPRESS

Pressing System

100% safety in 3 steps

100% safety in 3 steps

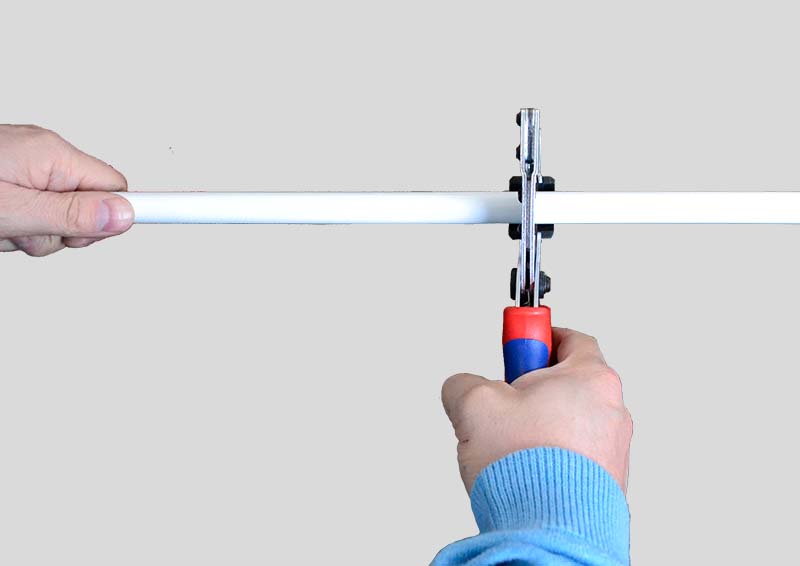

1. Cut

Cut the MAINPRESS composite pipe to length at a right angle using the corresponding original tool by MAINCOR.

2. Deburr

Then deburr the pipe until a circumferential bevel is evident. The bevel is necessary in order to prevent damage to the profile rings. The bevel must be checked before insertion. The correct insertion depth can be checked using the incorporated viewing window on the fitting.

3. Press

Put pressing jaws on the sleeve between the stops. Ensure that the pressing jaw abuts properly onto the stop ring. Then trigger the pressing procedure with the pressing machine. The pressing jaw must be completely closed at the end of the pressing procedure.

1. Cut

Cut the MAINPRESS composite pipe to length at a right angle using the corresponding original tool by MAINCOR.

2. Deburr

Then deburr the pipe until a circumferential bevel is evident. The bevel is necessary in order to prevent damage to the profile rings. The bevel must be checked before insertion. The correct insertion depth can be checked using the incorporated viewing window on the fitting.

3. Press

Put pressing jaws on the sleeve between the stops. Ensure that the pressing jaw abuts properly onto the stop ring. Then trigger the pressing procedure with the pressing machine. The pressing jaw must be completely closed at the end of the pressing procedure.

Properties

Properties

![]() Flat sealing ring

Flat sealing ring

![]() Unpressed leaking

Unpressed leaking

![]() Compatible with all U-profile systems

Compatible with all U-profile systems

![]() 10 years extended warranty

10 years extended warranty

![]() 100% oxygen-tight

100% oxygen-tight

![]() Dim. 16 - 63

Dim. 16 - 63

Also available as bars, pre-insulated and pipe-in-pipe

DE Version

DE Version